Why all supply chain optimization efforts need to be process-led in 2023

If there’s one thing everyone working in supply chain can agree on, it’s that today’s model for supply chain isn’t meeting today’s demand.

Shifting consumer demand, stockouts and shortages, and global macroeconomic turbulence have put pressure on supply chains, and the way they’re currently built doesn’t have enough visibility or flexibility to roll with the punches.

So, supply chain optimization is the name of the game. But transformation efforts thus far haven’t garnered the results anyone was hoping for.

We think there’s a very good reason for this — and an answer to it — but before we get to that, let’s look at the challenge we’re trying to solve.

Supply chain resilience is all about balance

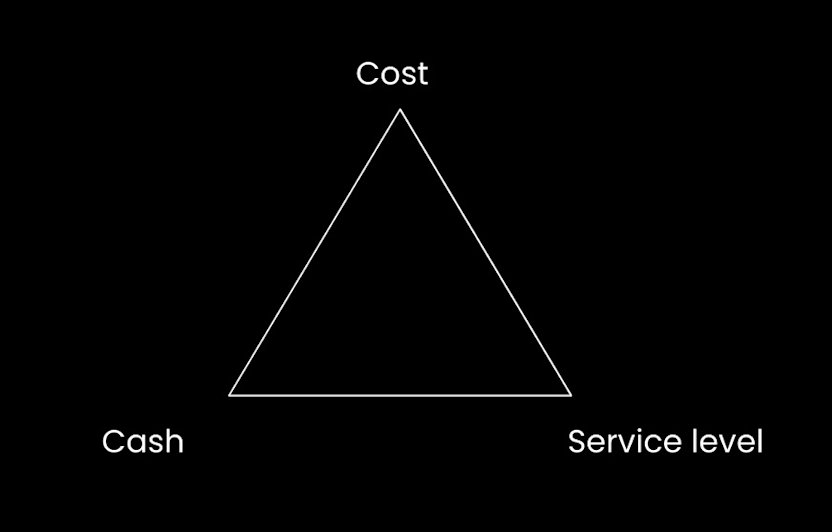

In order for supply chains to weather the storms we’re facing today — and whatever tomorrow throws at us — it needs to improve in three directions:

But the important thing about the triangle is that you really only have a high performing supply chain if the three points are in balance. If you improve your service levels but don’t optimize how you’re managing your inventory, then your supply chain simply won’t perform. And the same is true of any of the three points.

This poses an interesting challenge for supply chain leaders because it’s hard enough improving each of those three in isolation, let alone making sure that you’re doing all three in a balanced way.

A huge part of cracking that is about knowing how each part of the supply chain affects — and is affected by — all the other parts.

Supply chain visibility needs to be end-to-end or nothing at all

Typically supply chain visibility has been a hard nut to crack — the ubiquity of the “only 6% of companies have total supply chain visibility” stat from Geodis, despite the fact it’s from 2017, is testament to that — for many reasons, but primarily because supply chains are such complex things; run by many people, in many departments, using many different systems and processes.

So it’s practically impossible to see how each link in the supply chain affects, and is affected by, any other link. Like how the actions in Sales will directly affect the work for people in demand forecasting, which will directly affect those in procurement.

And because each link is both totally interconnected and totally siloed, you end up with a blame chain where everyone has metrics they can’t move, a feeling of disempowerment, and a lot of finger pointing.

Supply chain optimization needs to start process-first

The answer to this problem has been staring us in the face the whole time. Supply chains are one mega-process made up of lots of connected micro-processes, but traditional supply chain optimization attempts all fail to look at the very thing supply chains are made of: processes.

Because supply chain operations are governed by the processes contained within each individual link in the chain, fixing the individual processes has a huge impact on everything else. Like how you handle credit and delivery blocks. Adding intelligent automation at a couple of points can free up the flow of your whole supply chain.

By adopting a process-led supply chain transformation mindset, you can optimize your whole supply chain in a balanced way, by fixing the individual building blocks that make up the chain.

It’s the dawn of a new era for supply chain. And those who finally manage to crack transformation win big. Slick processes, stickier customer and employee experiences, and cost control tighter than a drum all make for competitive advantage that’s hard to beat.

Let’s get to it.

Want to dig a little deeper into what process-led supply chain transformation looks like? Check out some tangible use cases? The Celonis supply chain transformation page is calling.